What is a Winder Machine? Functions and Types

What Is a Winder Machine? A Comprehensive Guide for Modern Manufacturing

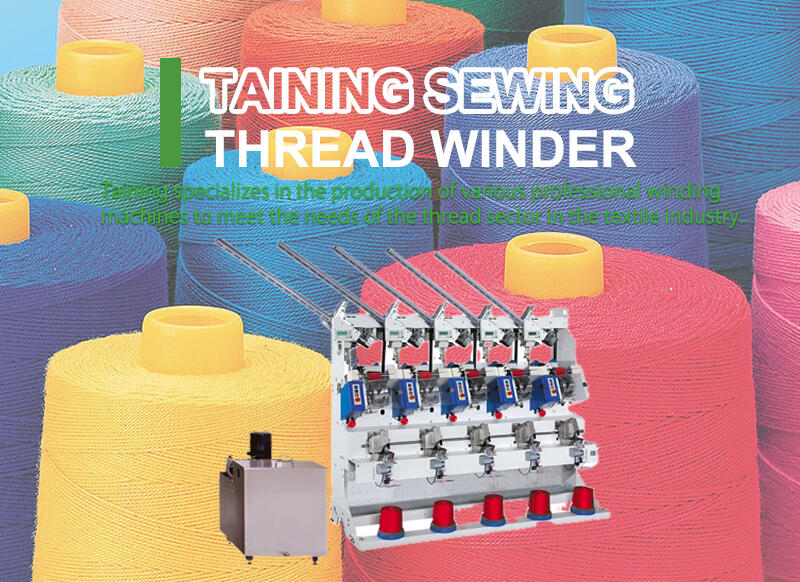

A winder machine is essential equipment in industries such as textiles, paper, cable, and film. It winds yarn, thread, bobbins, or paper rolls evenly onto cores or spools. Equipped with automation features—such as tension control, break prevention, automatic core replacement, and lubrication systems—winder machines ensure consistent speed and smooth feeding while boosting productivity and quality while reducing labor costs.

How Do Winder Machines Work?

Winder machines operate through a spindle driven by servo or inverter-controlled motors. A traverse mechanism creates precise, crisscross winding patterns. Optical or edge sensors detect core fullness, triggering automatic core changes. Meanwhile, tension regulation and automatic lubrication maintain thread integrity and winding quality. This seamless automation delivers high efficiency, consistent output, and minimal interruption—similar to how advanced automatic winders “eliminate risks” and support round-the-clock productivity.

Key Functions of a Winder Machine

- Even Winding — Automated systems ensure uniform winding—crucial for product consistency and avoiding defects.

- Sensor-Based Core Detection — Edge or optical sensors detect spool status and facilitate seamless core changes.

- Tension Control & Lubrication — Consistent tension and lubrication prevent thread breakage and enhance quality.

- Boosted Efficiency & Reduced Downtime — Automation means fewer rejects, less manual labor, and continuous uptime, enabling swift production scaling.

Types of Winding Machines

- Fully Automatic High-Speed Winders — Ideal for heavy-duty, high-volume production.

- Semi-Automatic High-Speed Winders — Combine automation with operator oversight.

- Fully Automatic Under-Bobbin Winders — Specialized for compact or delicate winding tasks.

- Benchtop Winding Machines — Compact models for small-scale or prototyping work.

Why Winder Machines Matter in Modern Manufacturing

- Unparalleled Efficiency — Automatic winders enable continuous, fast, and accurate operation—crucial in today's market where speed equals advantage.

- Superior Precision & Quality — Digitally controlled parameters ensure each product matches standards, reducing defects and elevating brand reputation.

- Downtime Reduction — With modular tooling, self-diagnostics, and remote monitoring, automatic winders minimize both planned and unplanned stoppages.

- Human-Machine Synergy — Operators are freed from repetitive tasks to focus on innovation and quality assurance, blending craftsmanship with automation.

Real-World Use Cases

- Textile Industry: Converting yarn into neatly wound bobbins or cones—critical in weaving preparations.

- Electrical Components: Coil winders produce windings for transformers, inductors, motors, and solenoids with precision.

- Motor Manufacturing: BLDC motor winders automate winding tasks across applications—from automotive to aerospace—ensuring consistency and throughput.

Conclusion

In essence, winder machines are the workhorses of modern automated manufacturing. From ensuring consistency and quality to enabling scalable production with minimal downtime, they offer unmatched advantages to textile, paper, electrical, and motor industries alike. Whether you're winding yarn, paper rolls, or intricate motor coils, the right winder machine brings precision, reliability, and efficiency to every layer.