Thread Winders: Super Important Machines in Textiles & Manufacturing!

What is a thread winding machine?

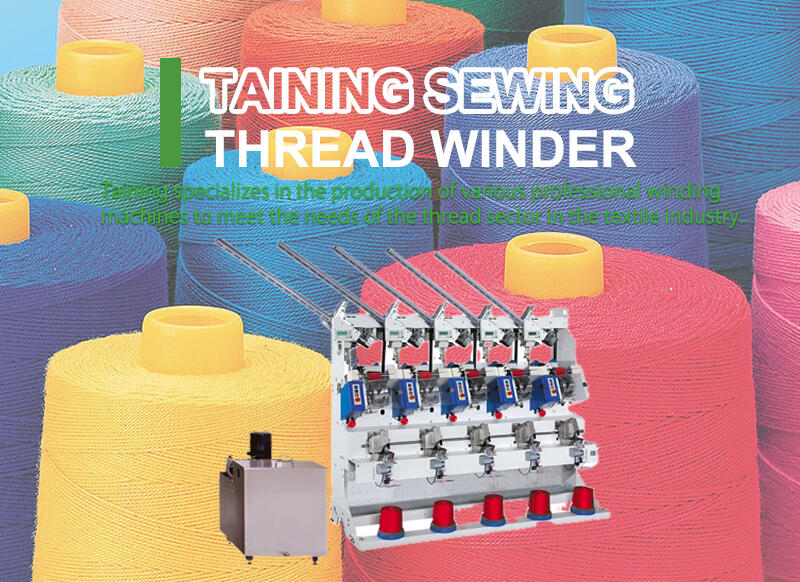

In yarn processing, what exactly is a thread winding machine? It is equipment designed to wind dyed yarn evenly onto tubes or spools. These machines can automatically change tubes, maintain consistent winding speed and tension, and include built-in lubrication systems. As a result, they improve winding efficiency and quality, reduce labor costs, and increase overall production.

What are the types of winding machine?

What types of winding machines are available? Taining offers a wide range of models: fully-automatic high-speed winders (types A, Y, H, i for Cone, King-Spool, Spool, and i-Spool), multifunctional combiner winders and semi-automatic cone winders, as well as fully-automatic winders specifically designed for bobbin and dental floss threads.

How do wind thread on a winding machine?

How does a winding machine operate? Using a computer or servo control system, it regulates the spindle’s rotational speed and the traverse mechanism. In combination with tension adjustments and an automatic oiling system, yarn is wound tightly and in alignment.

What is the function of thread machine?

What is the function of a winding machine? Its primary roles include standardizing tension, preventing thread breaks, reducing downtime from tube changes, and improving both productivity and consistency—all while reducing manual labor. Such machines are indispensable in textile, Garment factory, footwear, embroidery, and similar industries.