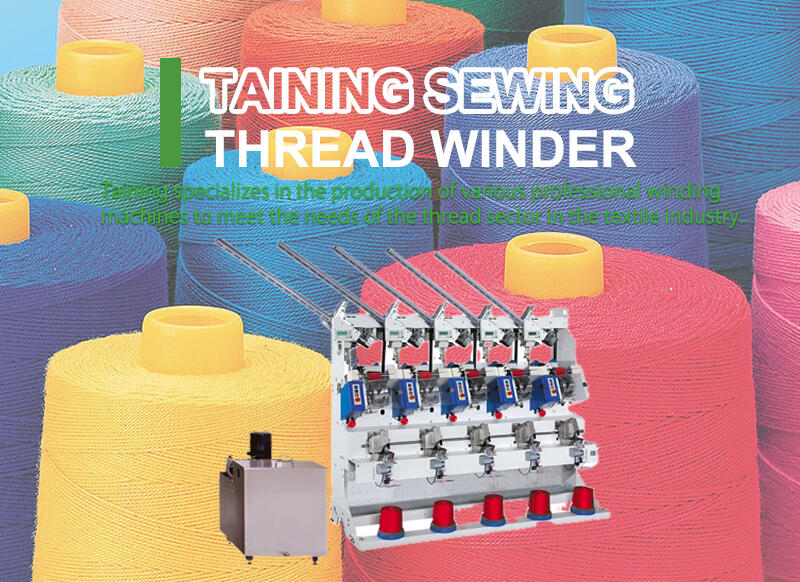

TN35AF-H TN35EF-H

Automatic Mechanical Bobbin Doffing System (5 Spindles) Spool type

- Automatic mechanical bobbin doffing system.

- Individual spindle control.

- One computer terminal (HMI)

- Auto lubrication system.

- Drum thread guiding system.

- Electro-magnetic tension device.

- Circulating oiling tank.

- 200 sets of memory functions with production quantity preset.